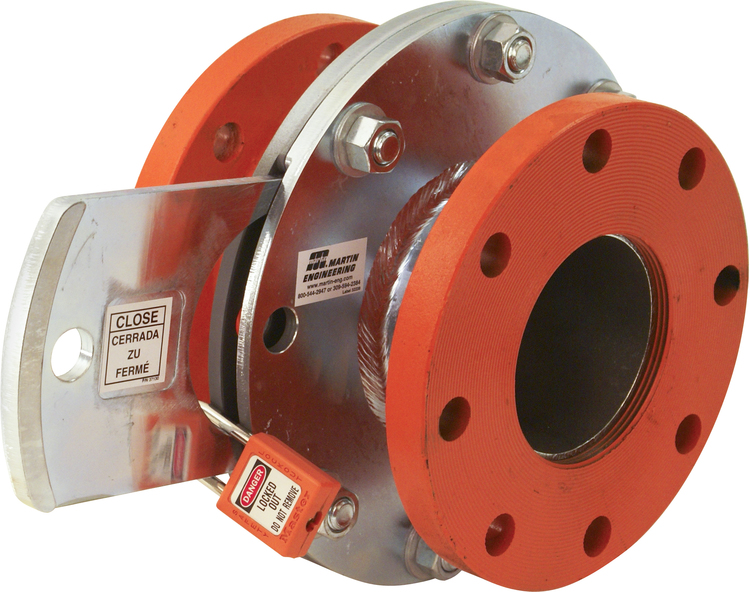

Thermo Safety Shield

The Martin® Thermo Safety Shield acts as a safety barrier to allow timely and safe maintenance of air cannon systems. It protects employees from exposure to severe temperatures so that maintenance can take place safely and productions stays on schedule.

Features and Benefits:

- Safety slide gate allows timely maintenance on air cannons in high temperature processes without risk of exposure

- Shelters workers from exposure to severe heat, gases and high temperature material

- Sliding shield operates under tough conditions, yet can be locked out to prevent intrusion

- Sliding shield bolts between air cannon valve and mounting flange

Options:

- Martin® Thermo Safety Shield is available for any air cannon with 4-inch or 6-inch discharge

Our technicians and engineers are available to provide expert advice and assistance on this product and all of your bulk material handling questions and problems. Please contact us today and let us help!

Air Cannons Eliminate Need For Water Blasting

Air Cannons Prevent Buildup on Kiln Walls

Flow Aid Solutions Reduce Production Outages At Cement Plant

Free Engineering and Application Assistance

Our technicians have solved problems for people in your industry all over the world. Take advantage of our wealth of knowledge. Tell us about your situation today to learn how Martin can improve your performance, safety and bottom line - with no obligation. We want to ensure that you choose the right solution for your exact needs and we are willing to invest the time upfront to get it right the first time.

Briefly Describe Your Application